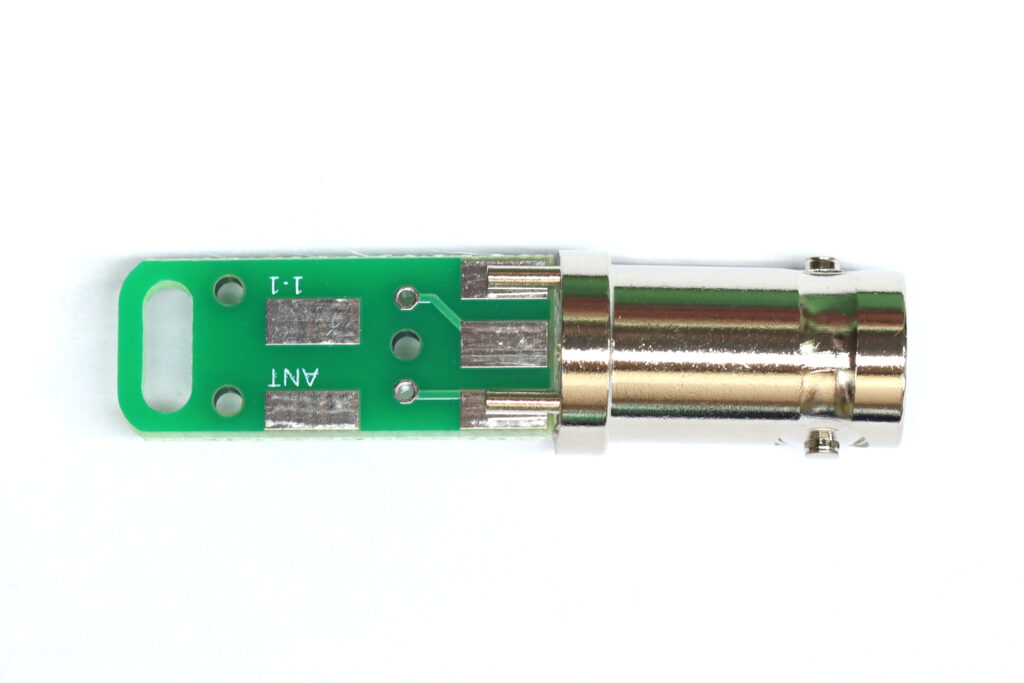

Step 1: Install PCB onto connector.

Clip two of the adjacent ground lugs off of the BNC connector and position the PCB onto the BNC.

Orient the board so the single rectangular solder pad on the “K6ARK EZ Match” text is in contact with the BNC center pin conductor.

Solder the center conductor and ground lugs to the PCB pads.

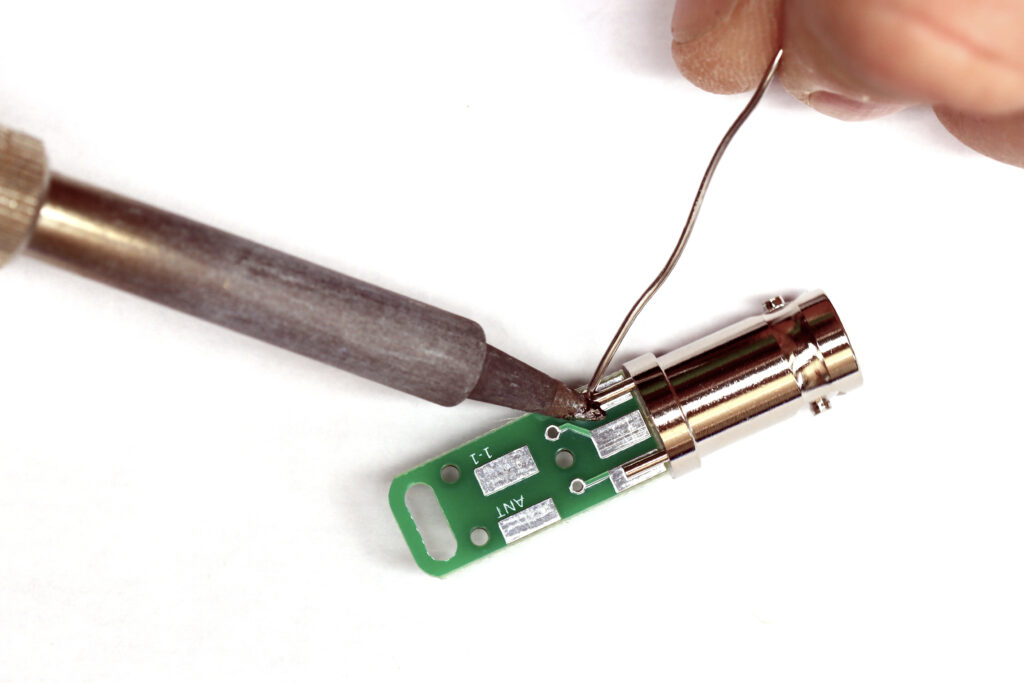

Step 2: Install counterpoise wire.

Note: The standard build for the 9:1 unun has the counterpoise wire exit the bottom of the matching unit. If you prefer to have the counterpoise wire exit the top of the unit, take a look at Step 7 in the 4:1 unun build instructions.

Cut the length of Poly Stealth wire roughly in half.

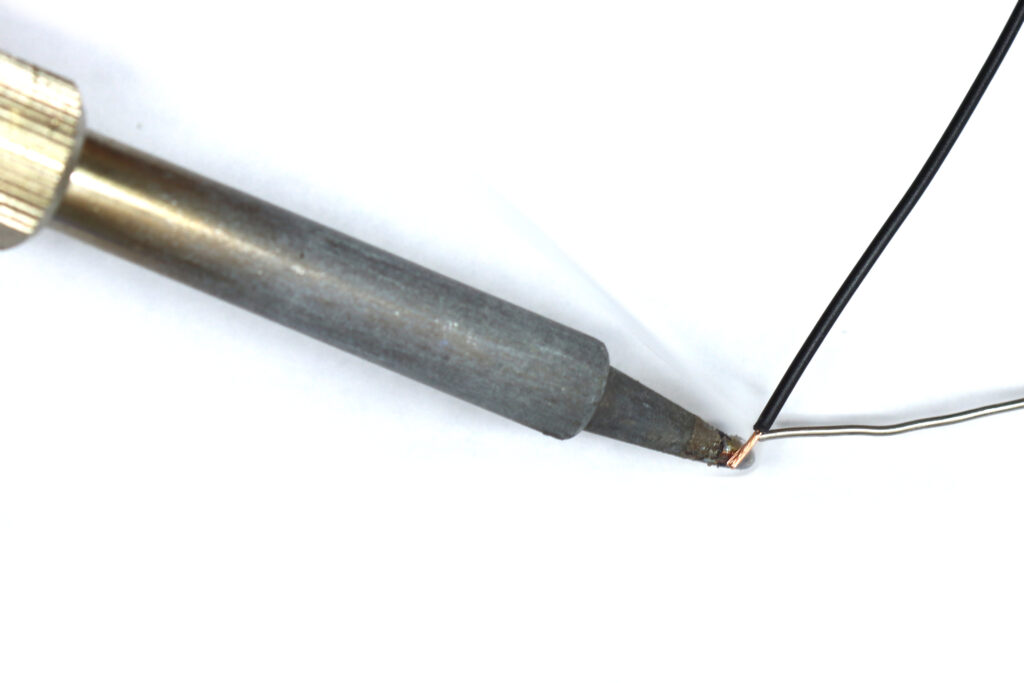

Strip about ⅛” of insulation from the end of each wire. Tin the stripped ends with solder.

Insert one piece of wire through the strain relief hole as shown, and solder the end of the wire to one of the ground lugs.

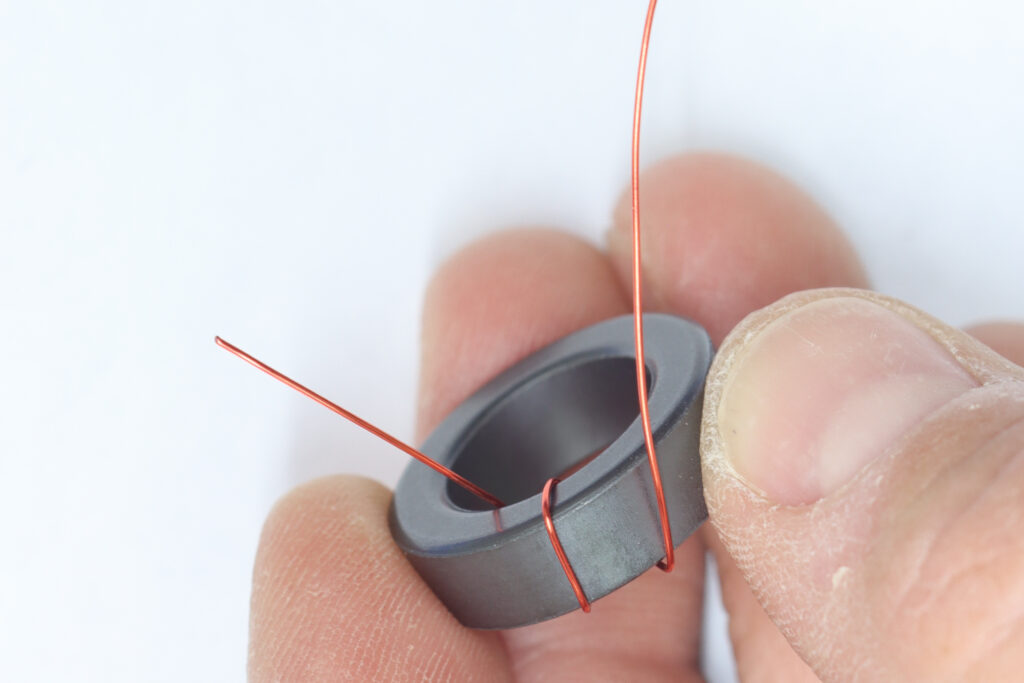

Step 3: Wind the toroid.

Begin winding the toroid as shown. Note the matching the direction of winding shown will ensure the wire leads align with the pads.

Begin winding as shown, and make 8 turns all the way around the toroid with wide spacing.

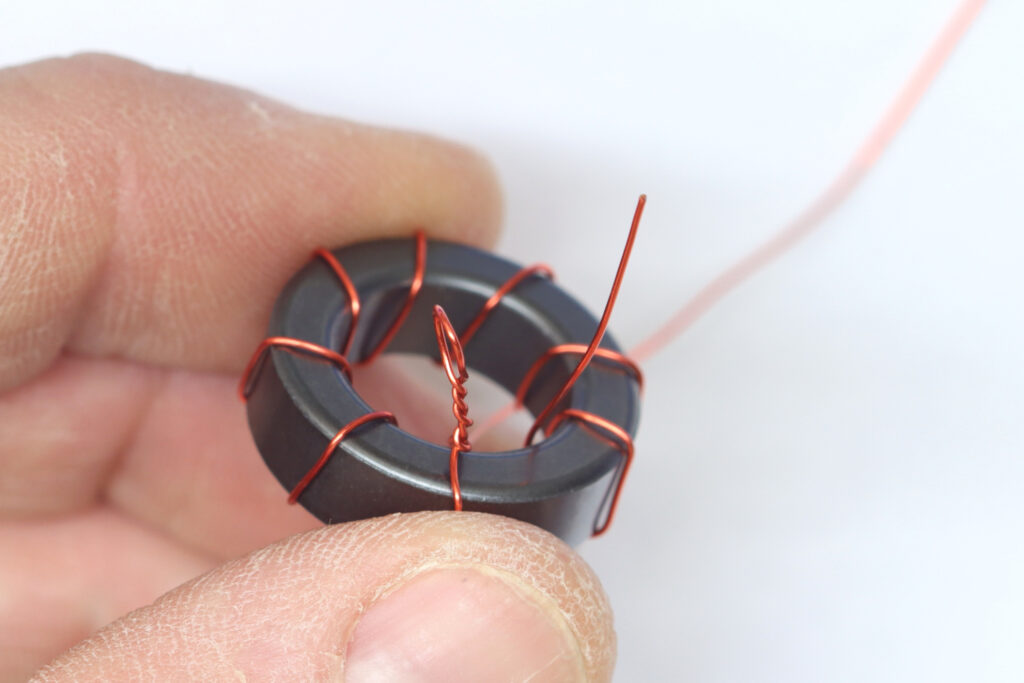

After 8 turns, create a twisted stub of wire, a tap, just before reaching the stub of wire where you started winding. After creating the stub, continue wrapping 8 more turns around the toroid.

I try to wrap the wires next to the 8 turns on the previous lap around the toroid so it’s easy to keep count, and it looks nice, but it is not necessary for the transformer to function properly.

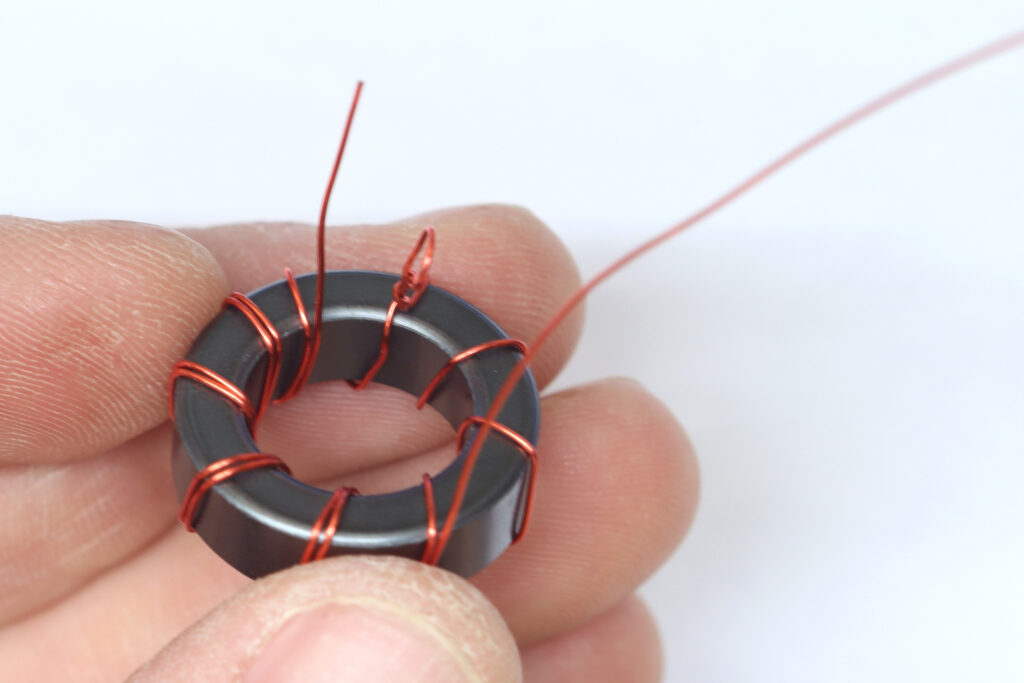

After finishing second set of 8 turns, continue winding 8 more turns, making one final lap around the toroid.

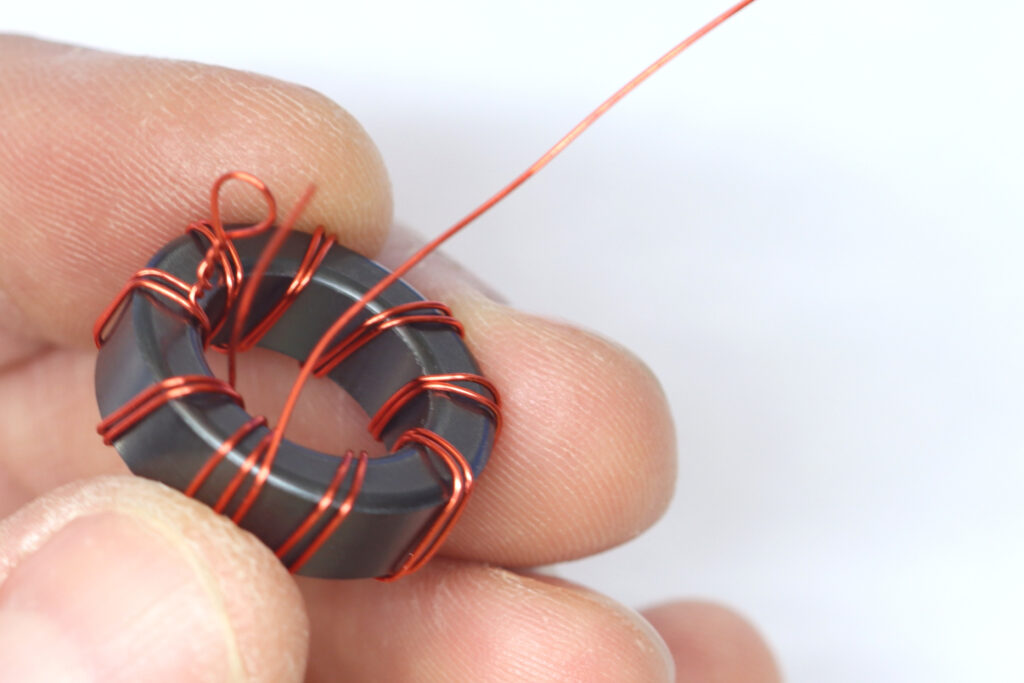

The final toroid should look like this.

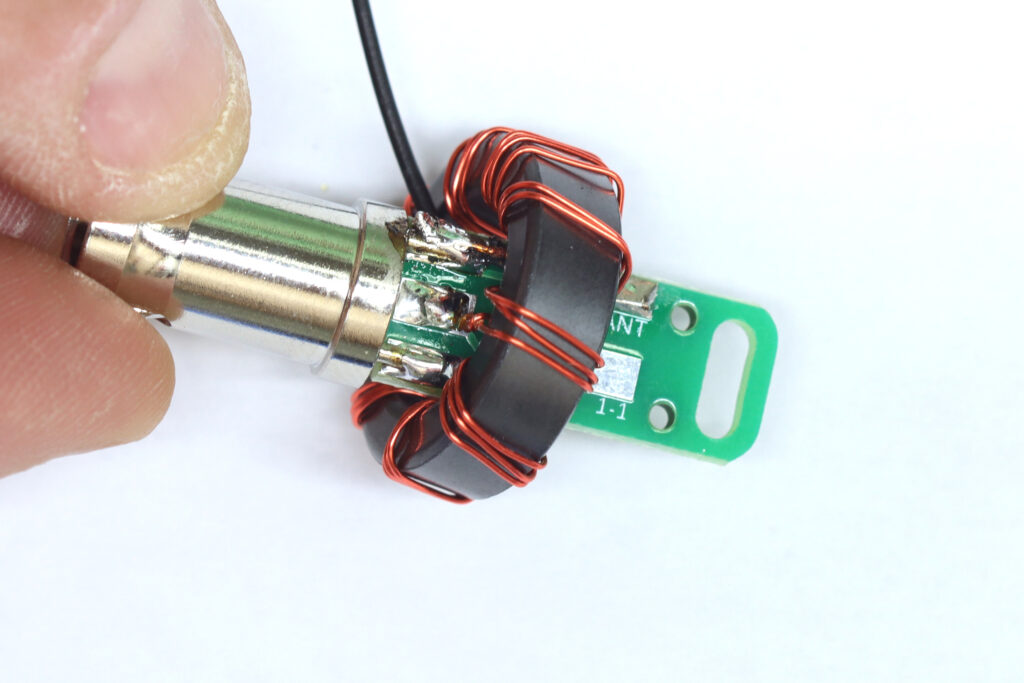

Step 4: Attach the toroid to the PCB.

Trim the wires to about 1/4″ in length. Tin the magnet wire ends with solder, burning off the enamel with a hot iron.

Solder the toroid to the PCB as shown. The single “start” wire next to the stub is soldered to a ground lug. The twisted stub is soldered to the center solder pad on the board as shown. The single “end” of the wire is soldered to the “ANT” pad.

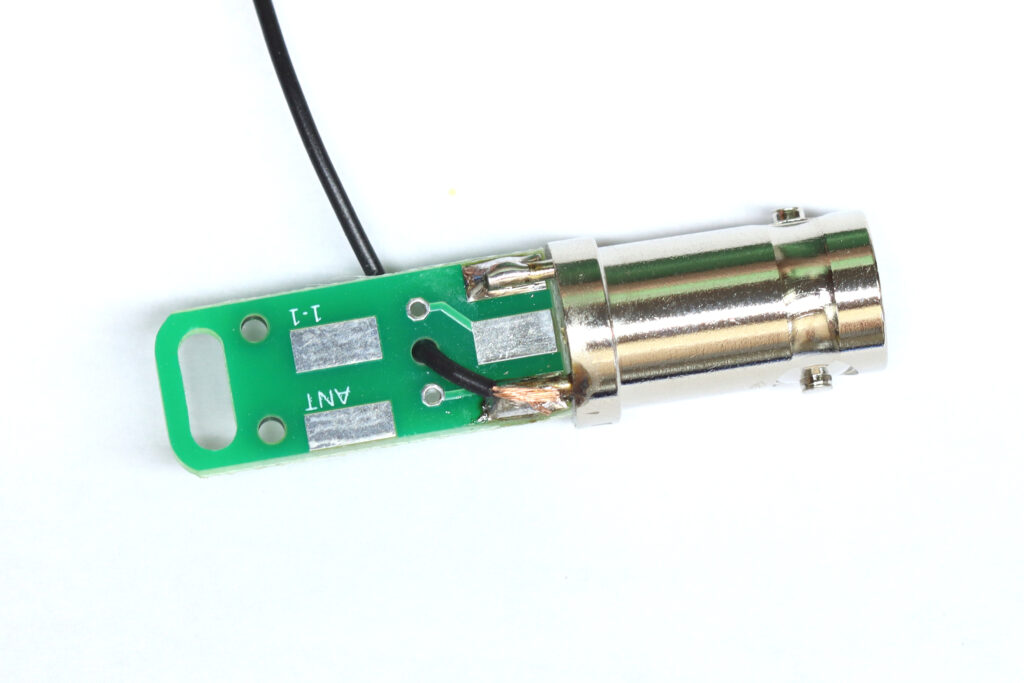

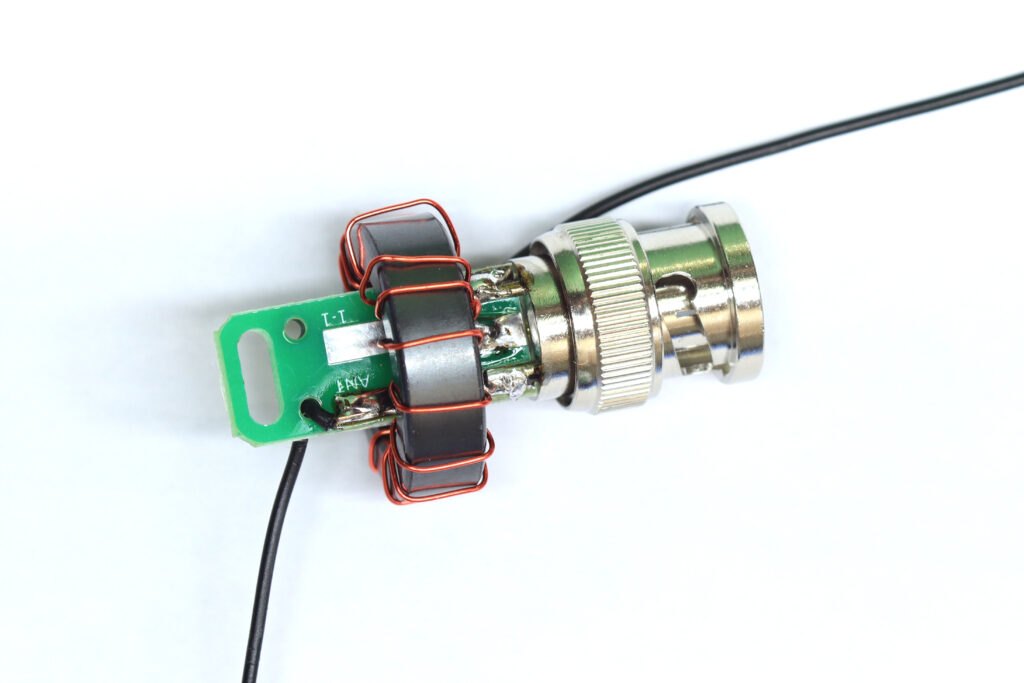

Step 5: Attach the antenna wire.

Take the other piece of black wire, or if you prefer to attach directly to your matching unit, the end of your antenna wire, and thread it through the strain relief hole near the “ANT” pad and solder the end to the “ANT” pad.

Step 5: Test the matching unit.

It’s a good idea to test the matching unit before installing the final heat shrink. You can test it by attaching a radiator and counterpoise and checking for tunable SWR across the ham bands (I like to use 17 ft counterpoise and 41 ft radiator for 40 – 10 m).

Another option is to attach a 450 ohm resistor across the ANT and Counterpoise wires and look for a relatively low SWR across the ham bands using an antenna analyzer.

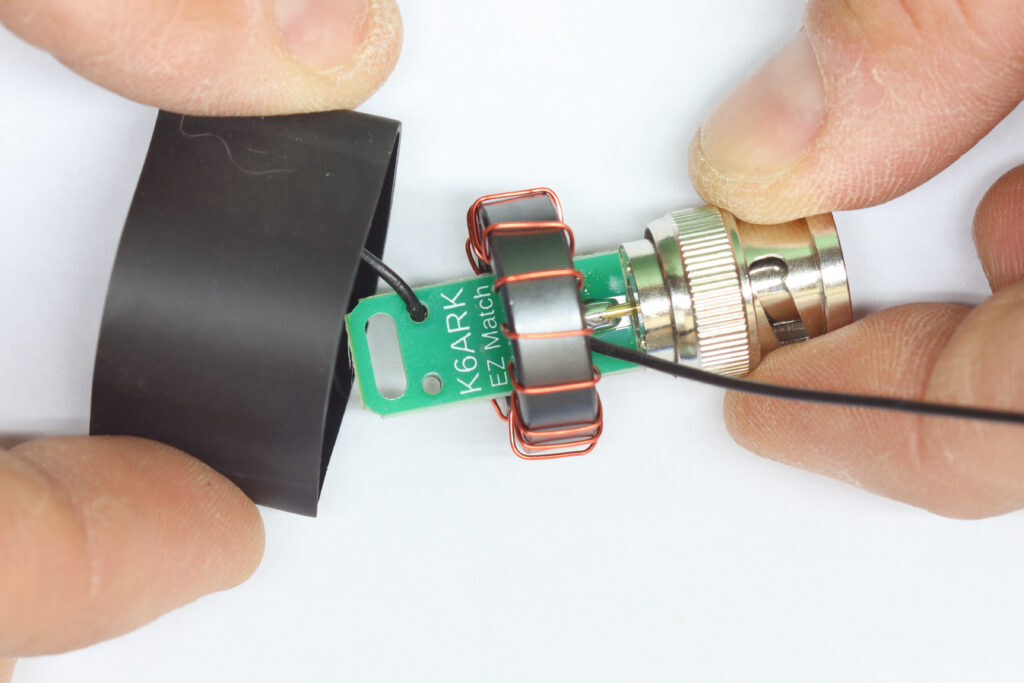

Step 6: Install the heat shrink tubing.

Place the shorter section of 1″ heat shrink tubing onto the matching unit and shrink into place as shown.

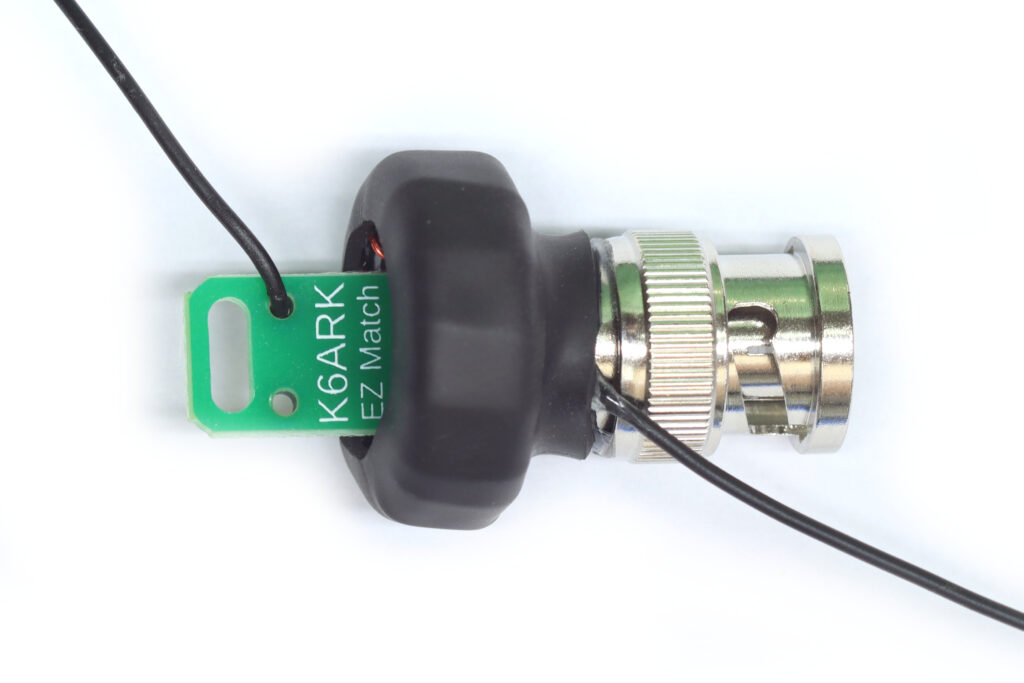

The finished unit should look like this (with your choice of connector, of course).

Step 7: Attach wire elements.

Attach a 17 ft counterpoise to the shorter wire stub (C-POISE). Attach a “random” length wire to the longer wire stub (ANT) – I recommend 41 ft which should be usable on 10 m through 80 m with a KX2, KX3, T-1 tuner, or Xiegu X5105.